1. Degreasing

Remove oil from the device.

(Degreaser, thinner can be used)

2. Cleaning

Wash the equipment from oil and garbage.

(Laundry detergent, detergent available)

3. Grinding

Paint oxide scale residue on sanding equipment.

(Professional grinding machine equipment)

4. Paint removal

Remove equipment damage, paint surface, metal surface, and rust removal.

(Professional grinder, angle grinder)

5. Primer

Anti-corrosion of the metal surface primer of the equipment.

(Anticorrosive primer)

6. Putty

The damaged surface of the equipment is uneven, and the putty is leveled.

(Putty for machinery and equipment)

7. Medium coating

The primer has good corrosion protection and adhesion.

(Epoxy zinc-rich primer, primer,)

8. Topcoat

The topcoat has a good aesthetic color.

(Acrylic topcoat for machinery and equipment)

Yingchi intelligent construction is safe and reliable

The painting conforms to the construction methods and operating procedures of the national standard

Before the paint renovation, remove all the existing old paint and remove the rust, so that the painting will not cause pimples on the mechanical surface during the renovation process, resulting in an unsmooth and uneven surface. Mechanical refurbishment paint requires a professional colorist to match the color, and the various paints are mixed together, and the colors are very different, and it is difficult for people without a certain amount of experience to do color matching. In the process of painting, experienced painters are needed to ensure that the paint is in place in each position and the color of the paint is matched in each position.

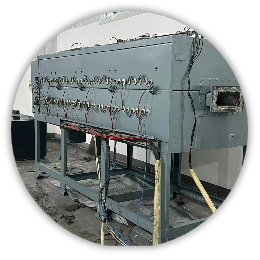

Comparison Chart