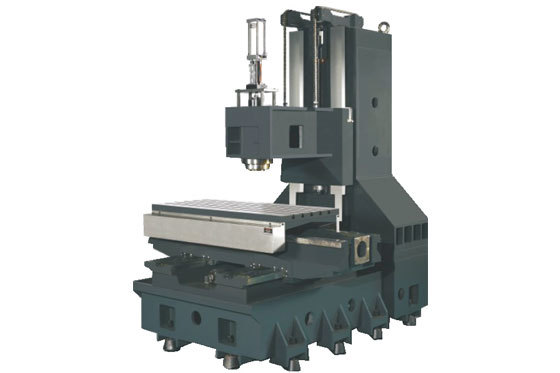

High rigidity mold hard rail machine series

Mechanical features:

The high-strength column and the base are stable, not deformed, can be displaced quickly, and the processing speed is fast, saving processing time.

Low inertia spindle design, high rigidity and high torque spindle, high stability, fast and accurate, widely used in the processing of various precision molds or large batches of common parts.

The high-quality cast iron worktable has good bearing capacity, high spindle torque, suitable for heavy milling of heavy-duty cavity or mold frame, and the workpiece milling speed is fast.

Category:

Product Description

High rigidity structure is the guarantee of heavy cutting

The best companion for molds

The machinery adopts box structure with good pressure characteristics.

The main shaft sleeve adopts the special bearing of precision grade main shaft, which is excellent in precision and stability.

Precision ball bearings are pre-tensioned to ensure thermal expansion precision.

The escort adopts the direct transmission of high-density coupling to reduce the transmission clearance.

| Model | Unit | YC—850 | YC—1690 | YC—1890 |

| Journey | ||||

| X-axis travel | mm | 1500 | 1600 | 1800 |

| Y-axis travel | mm | 800 | 900 | 900 |

| Z-axis travel | mm | 700 | 800 | 800 |

| Workbench | ||||

| Working desk size | mm | 1700×800 | 1800×900 | 1970×1000 |

| Maximum load | kg | 1500 | 1600 | 2200 |

| T-slot (width - number of slots x pitch) | m/min | 22-5×135 | 22-5×165 | 18-7×120 |

| Feed | ||||

| X, Y axis rapid traverse | mm/min | 15000 | 15000 | 15000 |

| Z axis cutting feed | m/min | 12000 | 12000 | 12000 |

| Spindle | ||||

| Spindle speed | r.p.m | 8000 | 8000 | 6000 |

| Spindle Specifications | BT50 | BT50 | BT50 | |

| Spindle horsepower | Kw | 18.5 | 18.5 | 22 |

| Other | ||||

| Positioning accuracy | mm | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Repeatability | mm | ±0.003/300 | ±0.003/300 | ±0.003/300 |

| Mechanical weight | kg | 12000 | 13500 | 16400 |

| Mechanical Dimensions | mm | 4300×3250×3300 | 4500×3400×3300 | 5100×3400×3300 |

Previous

Next

Get a free product quote

Related Products